Products

In the course of ELOGplan GmbH’s many years of planning and consultancy activities, a concrete need for logistical or systemic solutions which were not yet available on the market was identified in many clients.

For ELOGplan, this was always a reason to talk to the clients about their concrete problems; to generate ideas with them, develop a practical realizable solution, and finally to support the operative application. In the meantime, some of these solutions have been protected by patents or utility models, are however available for each client (waste originator) or service provider (waste disposal company).

The products and tools offered by ELOGplan today support large industrial operations with the optimisation of their waste management processes, especially with respect to a better and high-quality recycling of all waste, as well as a minimization of the volumes of waste which arise during production.

THE MULTIFUNCTIONAL CONTAINER (MFB)

The perfect solution for industrial waste disposal

CONTAINER for MOBILE AIRBAG DISPOSAL (since 2020)

The AIRBAG IGNITION CONTAINER is an innovative disposal solution for waste generators and waste management companies, which want to destroy large amounts of airbags themselves: efficiently and safely.

Disposal companies with an airbag disposal focus or vehicle manufacturers as well, who would like to organize the disposal in their dealer network have a high outlay when collecting this very special waste and delivering it to one of the few safe disposal facilities.

It does not make economic sense to commission third parties to dispose of airbags if there are sufficient large amounts (> 100,000 units p.a.), buying and operating an own ignition container, whether with mobile or stationary deployment, increases the availability, the average performance, and lowers the costs. The container for airbag disposal developed and operated by ELOGplan and in a slightly improved style since 2020 is also sold to interested companies in the waste disposal industry or service providers closely related to the automotive industry.

Waste disposal companies and service providers can realize efficient and safe solutions with the ELOGplan container system, can better plan and lower costs as well as ensure a 100% recycling quote as thermal treatment is not required.

ELOGplan also offers consultation to clients in the airbag disposal industry and at the start of 2021 initiated a European network for airbag disposal specialists: NEAR (Network of European Airbag Recyclers). The aim is to advocate for a high quality and safe destruction of airbags and the prevention of used airbags being brought into circulation.

Storage and transport container für High Voltage (since 2021)

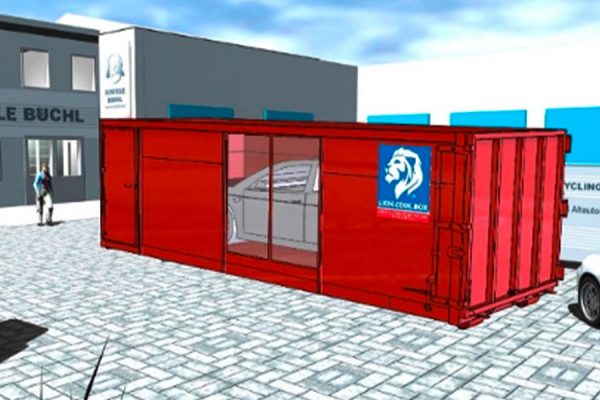

The development of a special container for storing and transporting High Voltage batteries from e mobility and e vehicles took place based on our own patent: the LION.COOL.BOX.

New solutions for safe storage and safe transport for critical High Voltage batteries or e vehicles which have had accidents are necessary due to the strong increase of e vehicles in passenger cars and other vehicle segments. Maximum safety in case of fire, flexible deployment, and container exchangeability are client demands.

The LION.COOL.BOX is a normed roll-off container for storing and transporting batteries and vehicles. The container has integrated temperature monitoring, several integrated extinguishing systems and can self-sufficiently and independently detect and extinguish fires. The extinguishing agent can be recycled to reduce disposal costs.

Waste disposal companies, towing companies, recyclers, disassembly operations, fire brigades can solve storage and transport problems using only one system with the LION.COOL.BOX. Clients, which need safe storage can rent the system and thus avoid considerable storage costs and quarantine regulations. The containers are exchanged for disposal and not separately loaded. Self-sufficient, safe transports are possible for critical vehicles and batteries.

The development, construction, and marketing for the LION.COOL.BOX is in cooperation with AMTEC ABT, a specialist for containers and temperature-controlled bodies. Demonstration containers are available in the 1A Autodemontage operation, Ingolstadt.

ELOG SYSTEM 4.0

ELOG SYSTEM is a holistic solution for the internal waste management logistics, especially in the automotive and automotive supply industry. ELOG SYSTEM consists of logistics systems and controlling. The system which has been in use since 2000 has been refined several times; Version 4.0 is currently in use.

Internal waste disposal in the area of production and installation is characterised by a number of small origins of waste, a lot of waste, concrete requirements for waste separation and constant adjustments (volumes, types of waste, storage spaces). It is a great logistical challenge to collect the numerous types of waste in small amounts from continuously changing origins of waste. In addition, disposal from the belt or “Just In Time” disposal, black/white areas separation or forklift-free disposal is also mostly requested.

The ELOG SYSTEM® next to meaningful planning for the internal operations waste management logistics (see WASTE PLAN 4 PLANTS) supplies a comprehensive approach with optimal containers, new transport systems, and a digital control for an internal logistical waste management solution. Special requirements from production operation such as forklift-free waste management, separating black/white areas, collecting containers on a need basis, integrating own container systems, using loading facilities or taking over defined supply jobs can all be realized with the ELOG SYSTEM. Some of the key components of the ELOG SYSTEM, such as forklift-free shuttles or multifunctional containers are specially developed for internal operation deployment.

Internal transportation is minimised, the sorting of the waste improved, the recycling quote increased, and costs made visible and reduced with the ELOG SYSTEM. The ELOG SYSTEM integrates existing internal transhipment and pre-treatment facilities (e.g., compactors, waste centre etc.). The clients’ preferred collection systems (e.g., recycling bags, boxes) are integrated. All the appointments generated by the software for individual collection jobs are adjusted to need by a special control system in the ELOG SYSTEM; reducing transports and releasing employees. The ELOG SYSTEM even optimizes itself! The digitalized controlling gives the process a quantum leap: through automatically generated jobs, their allocation to transport (e.g., a towing machine) and the handheld supported job processing (feedback, fill level, quality problems). The client not only has an overview of the number of jobs (and waste amounts) available anytime, but also precise data related to each origin of waste. The waste generator gains a coherent holistic system which encompasses all types of waste from the container equipment through the transport systems and transhipment facilities up to controlling with the ELOG SYSTEM. Combining it with a holistic planning is recommended.

Industry 4.0 in waste disposal starts with ELOG SYSTEM 4.0!

WASTE PLAN 4PLANTS

WASTE 4 PLANTS is a planning scheme for efficient plant disposal in large companies. With the standardized tool, the experts from ELOGplan plan a sustainable and cost-optimized internal disposal. It contains detailed planning for the optimal container equipment, necessary handling systems, concepts for waste separation and sorting as well as customized solutions for logistics and organization.

BENCHMARK TOOL

The BENCHMARK-TOOL is a database that is managed globally, across compensation and industry-specific with analysis tools for identifying waste avoidance and waste recycling potential in production companies.